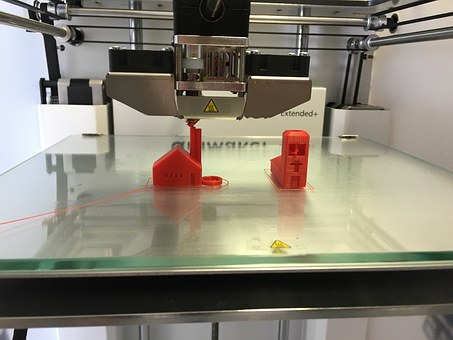

3D Printing, also referred to as Additive Manufacturing (AM) by some, consists of a set of technologies for 3D object creation by adding the material — which varies with every technology — layer after layer. This kind of manufacturing isn’t mainstream just yet, but it has terrific potentials to cater to a wide range of use cases. While 3D printers like Konica Minolta 3D Printers are designed for professional and commercial purposes, 3D printers for home uses are slowing making their way into the market.

The basic types of 3D printers and printing processes are pretty much similar to that of the 2D printers. Some printers only print text, while others can print text and graphics. However, the technologies and materials used are different from 2D printers. That said, let’s look at the different types of 3D printers available today and their uses.

- Stereolithography (SLA) – If your project requires real 3D printing of object models for design prototypes, then you can use SLA — one of the oldest 3D printing methods that’s still functional. The SLA method of 3D printing has the ability to convert liquid plastic material to solid objects in three dimensions.

- Digital Light Processing (DLP) – The method is very similar to SLA and finds its capabilities in production of movie projectors, 3D printing, and cell phones. But what makes SLA and DLP processes different is the use of different light sources. Unlike SLA, DLP utilises arc lamps for conventional light source.

DLP 3D objects are exceptionally advanced and robust in resolution. The technology requires much less use of material. Therefore, it results in less cost and incredibly less amount of waste while producing detailed prototypes.

- Fused Deposition Modeling – Leveraging this technology, you can print final end-use products, concept models, and functional prototypes. The technology is quite popular in engineering thermograde plastic, delivering the high performance. It is highly beneficial for manufacturers and mechanical engineers.

- Selective Layer Sintering – The technology uses laser to create 3D objects that uses powdered material for vat. The technology doesn’t employ support structures. Printers working on this technology are quite expensive as they use lasers of high power.

- Laminated Object Manufacturing – This is a system of rapid prototyping that has gained a lot of popularity because of its affordability and speed. The raw materials used in the process of prototyping is inexpensive, where the printed objects are bigger in measurements. This method find its application in the field of product development, architecture, and drawing.

- Selective Laser Melting – The technology uses highly powered beam of laser to create 3D objects by fusing and melting together the metallic powders. SLM works well for complex geometry structures and parts with hidden channels or voids and thin walls. SLM can be used when component designing is difficult. Medical orthopedics and aerospace manufacturers use Selective Laser Melting.

- Electronic beam melting – EBM is basically a technique called as “Power Bed Fusion.” The technology delivers less amount of material, not to mention the process is slow in comparison to the other techniques. All things being equal, there are many manufacturing processes that still use this method. The materials EBM technique uses are Inconel 718, Titanium, and Inconel 625.